Highlights:

Highlights:

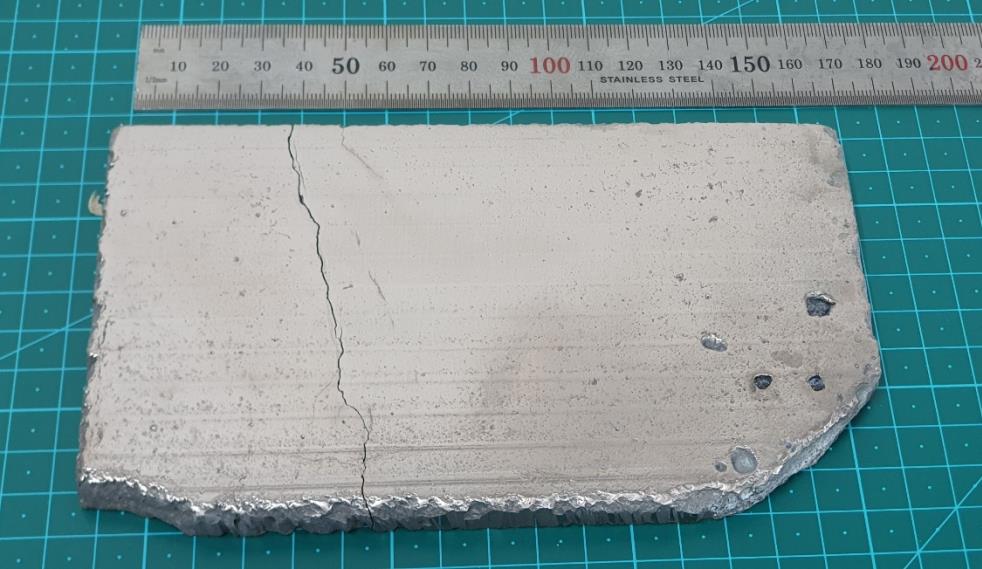

- High purity titanium (Ti) metal 20.8kg produced assaying 99.83%

- Innovative metals process confirms 70% lower energy consumption

- Ziron Tech optimisation increase metal efficiency by 50%

- Significant environmental benefits of innovative metal process confirmed

ASM’s joint venture (JV) has produced 20.8kg of high purity titanium metal (99.83%) confirming the energy usage at approximately 30% of the standard titanium industry processes. This innovative metal technology energy usage is 35 kW per kg compared to the industry standard Kroll process that uses 117 kW per kg of metal, and shows significant environmental benefits.

ASM Managing Director, David Woodall said: “Being able to successfully produce high purity metal without incurring the traditional environmental impact is a very significant result for ASM. Our JV team has achieved this result using 70% less energy, with none of the environmental contaminants of comparable titanium industry methods.”

“We are focussed on ensuring these high purity permanent magnet metals and titanium metals do not cause the environmental impacts of traditional methods. With our exclusive worldwide licence to commercialise this clean and environmentally responsible metal-refining technology, ASM is well-positioned in its strategy to add value to all Dubbo products.”

“ASM’s focus is now on commencing a metal plant feasibility which will confirm the optimal size of a plant in Korea, with the opportunity to build additional plants in key manufacturing areas in Australia, North America, and Europe.”

Highlights:

Highlights:

Highlights

Highlights