Highlights

Highlights

- ASM produced 120kg of titanium copper alloy (99.5% purity), confirming the commercial scalability of its innovative metallisation process.

- Improvements to ASM’s metallisation process has doubled the metallic yield.

- ASM continues to work collaboratively with Dongkuk R&S, on the potential to develop a full-scale metal processing facility.

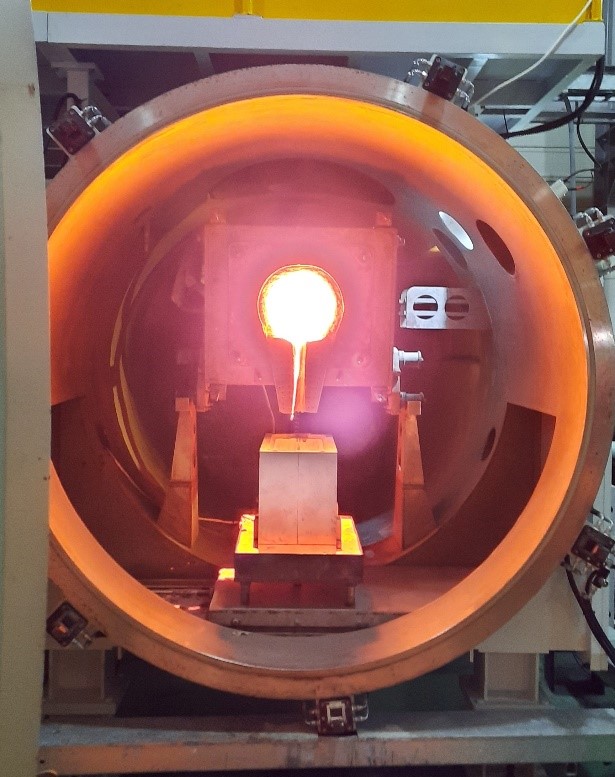

ASM has successfully confirmed the commercial scalability of its innovative metallisation process with the production of 120kg of titanium copper alloy (99.5% purity) at its facility in Korea. ASM’s Ziron Tech team produced two 60kg runs of the titanium copper alloy at a rate equivalent to approximately 1,000kg per day.

This result is significantly above the targeted 250kg per day production rate, outlined in the agreement between ASM and Dongkuk Refractories and Steel Co Ltd (DK R&S), announced on 2 November 2020.

The key to the successful demonstration of the commercial scalability was due to proprietary improvements to ASM’s unique metallisation process, which has seen the efficiency of metal recovery more than double than the initial test work in the pilot plant. This test work confirms the ability of ASM to produce any type of titanium alloy traded in the global metal market.

This increase in efficiency was delivered while maintaining the environmental advantages of ASM’s low-energy metallisation process, compared to the standard industry process. ASM will now focus on accelerating the development of a larger metals plant in Korea through its agreement with DK R&S. Members of DK R&S’s management and technical team were present to witness the successful metallisation run using the improved process.

ASM Managing Director, David Woodall said, “The successful commercial production run of titanium metal alloy is a significant result for the ASM team in Korea. What is even more pleasing is that this result was achieved using a proprietary improvement to our metallisation process, which has more than doubled the metal yield. We continue to discuss with DK R&S how we can accelerate the development of a metal processing plant in Korea.

“In addition to producing metal products from our Dubbo Project in central west NSW, ASM now has the potential to develop a significant business unit around titanium and other metals. This provides a tremendous foundation for ASM and its shareholders.”