Highlights

ASM Korean Metals Technology

- High purity titanium (Ti) metal 20.8kg produced assaying 99.83%

- Innovative metals process confirms 70% lower energy consumption

- Ziron Tech optimisation increases metal efficiency by 50%

- Significant environmental benefits of innovative metal process confirmed

- Production of 7.6kg of neodymium metal at 99.8% purity

- Production of 5.3kg praseodymium metal assaying 99.3% purity

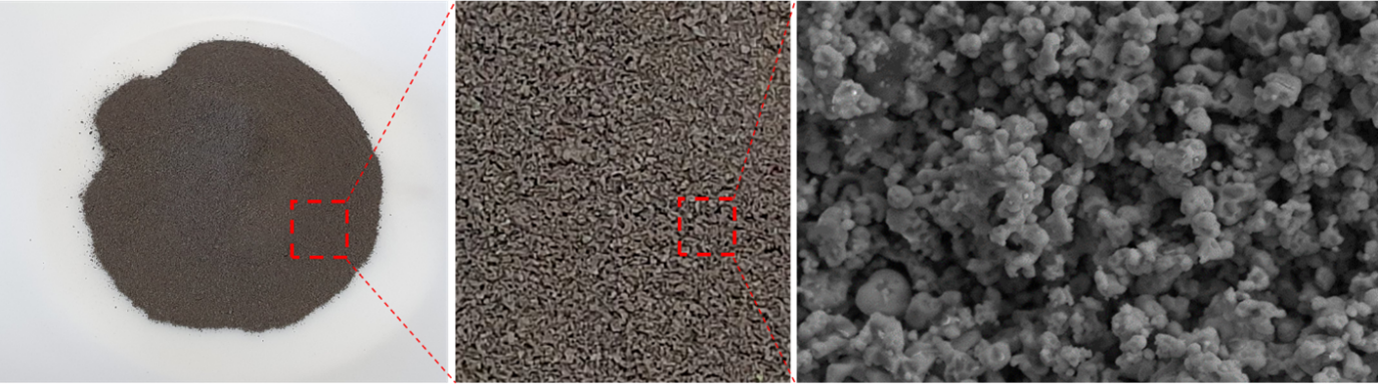

- Production of 9.2kg of titanium metal powder assaying 99.83%

- Production of 9.0kg of Neodymium Praseodymium (NdPr) alloy assaying 99.65%

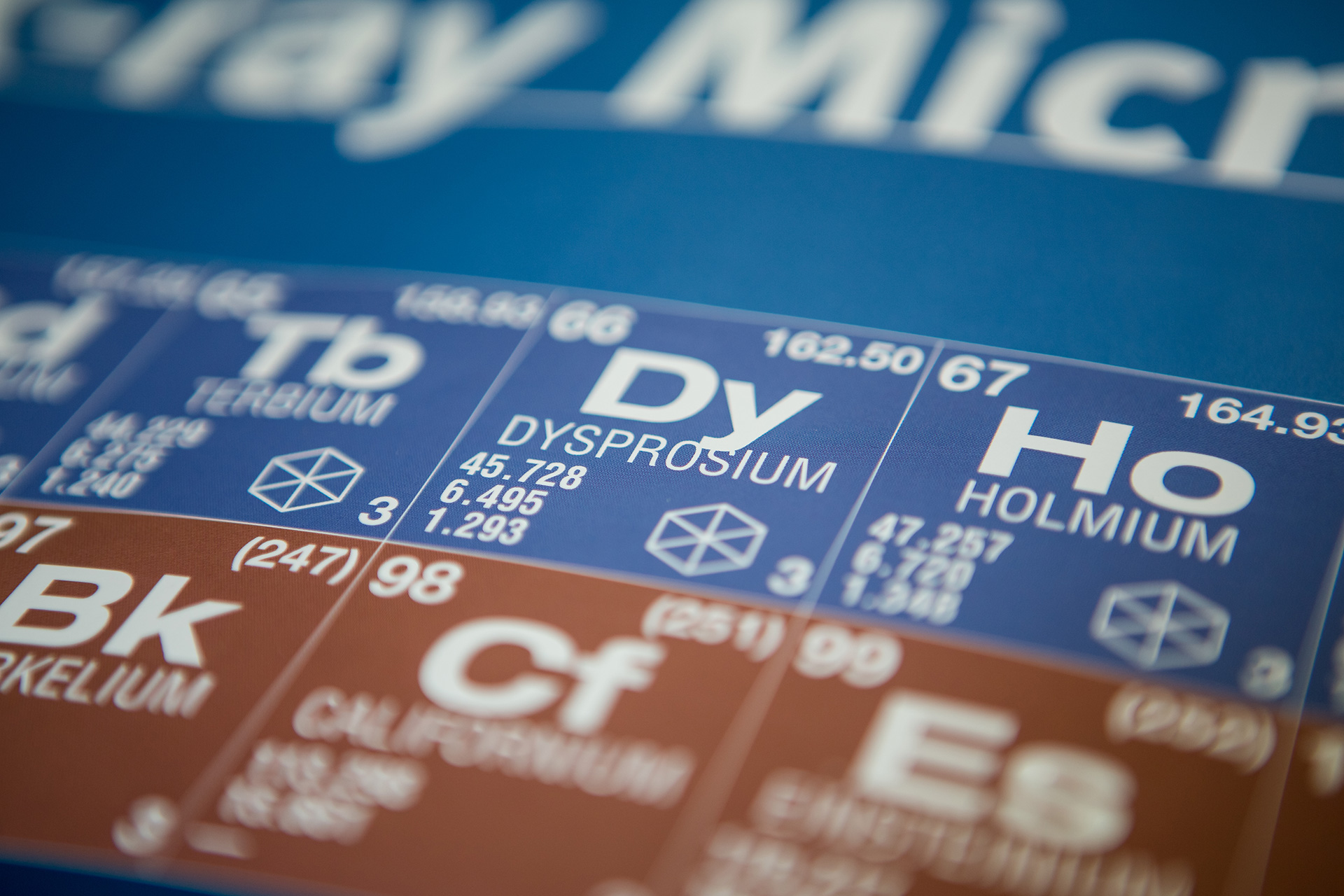

- Production of 7.5kg of heavy rare earth dysprosium metal assaying 99.53%

Optimisation of the Dubbo Project

- Work completed on initial flotation test work programme to deliver an increased ore feed grade to the solvent extraction plant. The integration of flotation into the proven flowsheet is a key part of targeting a reduction in the capital and operating costs for the development of the Dubbo Project.

- Production of metals from the Dubbo Project products have confirmed the proven flowsheet.

- Key products defined as zirconia, dehafniated zirconia for zirconium metal production and hafnium oxide; rare earths in the form of oxides for neodymium, praseodymium, dysprosium and terbium, and niobium.

- Hatch engineering has been engaged to complete the optimisation study by the end of the first quarter 2021.

Corporate

- Successful demerger from Alkane Resources Ltd

- Cash position totalled A$16.5M

- Acquisition of a 95% interest in joint venture partner Ziron Technology Corporation (Ziron Tech)

- Ziron Tech acquisition gives ASM ownership of all associated intellectual property including patented metal-refining technology

- Ziron Tech team will continue development of metallisation technology within ASM

Highlights:

Highlights: