Highlights:

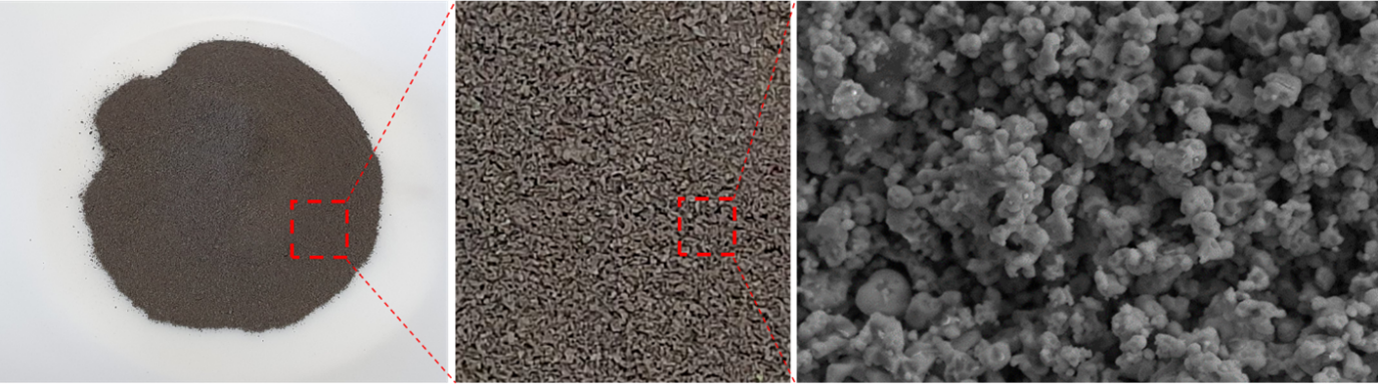

- ASM produces 8.6kg of high purity Zirconium metal powder

- Zirconium powder assay – 98% Zr and 1.5% Hf

- Confirmation of zirconium metal sample meets the Korean Atomic Energy Research Institute standards

ASM, through its partner Ziron Technology Corporation (Ziron Tech), has successfully produced 8.6kg of a high purity zirconium metal at its commercial pilot plant in South Korea.

The planned flowsheet for ASM’s Dubbo Project in central west NSW, incorporates the production of both industrial grade zirconia and dehafniated zirconia (ZrO2) and hafnium oxide (HfO2) using a process patented by Australia’s Nuclear Science and Technology Organisation’s (ANSTO) with ASM having an exclusive global licence. Successful production of this high purity zirconium metal from commercial grade zirconia is an important milestone for ASM.

Ziron Tech has received confirmation that the laboratory sample of dehafniated zirconium metal previously produced from Dubbo ore and submitted to the Korean Atomic Energy Institute (KAERI) meets the standards set by them that are crucial for the Korean market, with further work planned to produce 2 tonnes of high purity dehafniated zirconium (Zr) before the end of the year. ASM has now successfully produced key permanent magnet metals of neodymium, praseodymium, neodymium-praseodymium alloy, dysprosium, titanium metal, titanium alloy, titanium metal powder, and zirconium using its innovative metallisation process.

The focus is now on the production of 250kg of Neodymium-Praseodymium (NdPr) metal, to be turned into sintered permanent magnets samples in partnership with the Korean Institute of Rare Metals (KIRAM) for the Korean market. Work on the production of ferro-dysprosium and ferroniobium is scheduled for Q4 2020, which will mark the completion of the metallisation of the final products sourced from the Dubbo Project.

ASM Managing Director, David Woodall said: “The production of zirconium metal is a significant result for ASM and the potential development of the Dubbo Project. The successful production of zirconium and the other metals planned to be produced at Dubbo has enabled ASM to optimise the project flowsheet. In the 2018 FEED Study, the plan was for the project to produce predominately zirconium oxychloride (ZOC), today’s result will see the percentage of ZOC reduced significantly to focus on and meet the high purity zirconium metal and hafnium production targets, with potential benefits in the capital and operating costs.”

“I am returning to Korea to continue investment discussions, oversee the design and construction of a 250 kg per day continuous metal plant in Korea, and to continue advancing discussions for a potential partner in the metal business.” Mr Woodall said.