Highlights:

Highlights:

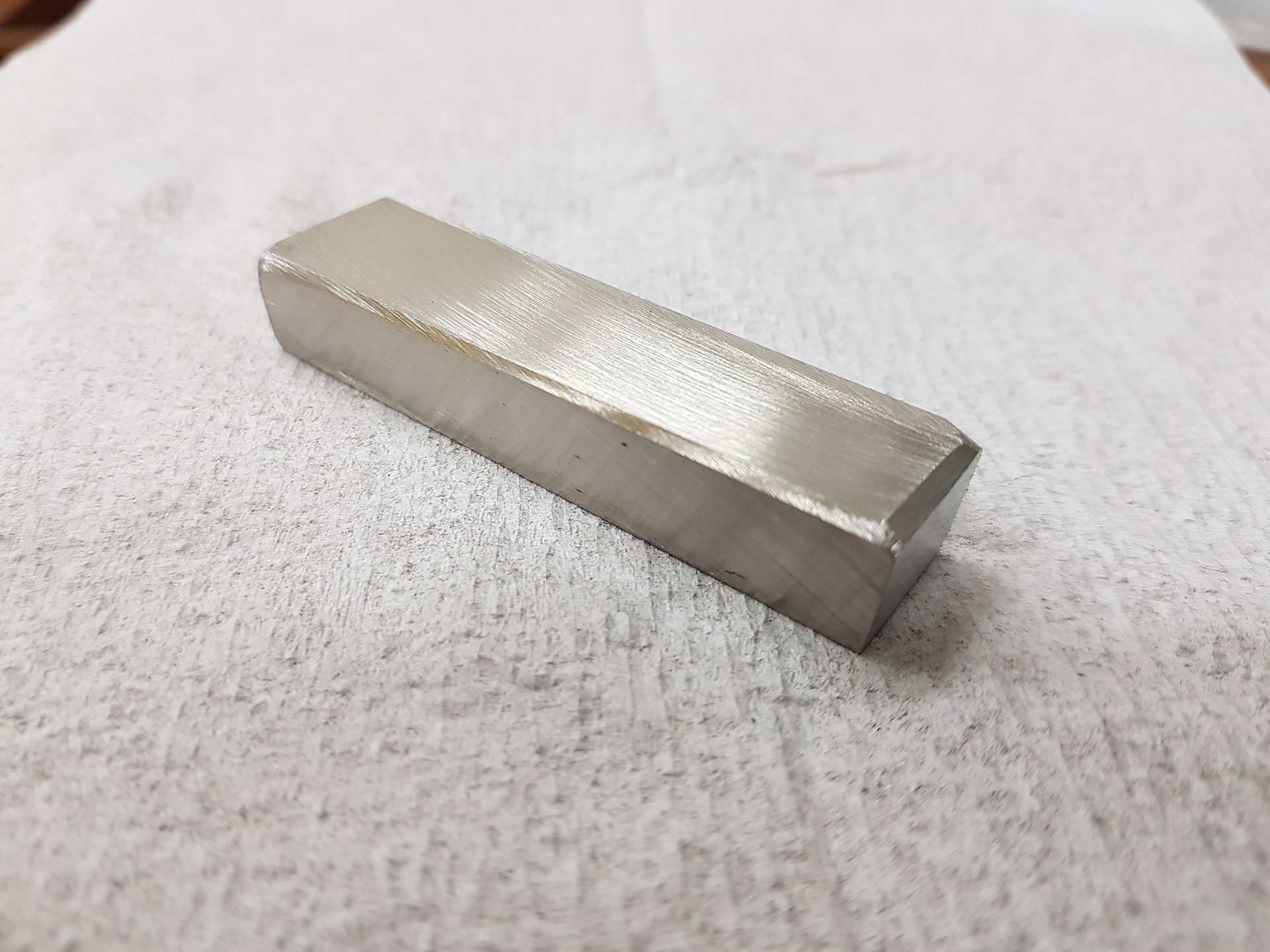

- ASM produces 0.76kg of heavy rare earth metal dysprosium (Dy)

- Dysprosium assay – 99.6%

- Metallisation process proven for the Dubbo Project’s key permanent magnet rare earth products (dysprosium, praseodymium and neodymium)

ASM, through its partner Ziron Technology Corporation (Ziron Tech), has successfully produced high purity dysprosium (Dy) metal in its laboratory at the Ziron Tech facility.

This work using the ASM metallisation process has confirmed ASM’s ability to produce the key permanent magnet metals (dysprosium, praseodymium and neodymium) and alloys that will be sourced from its Dubbo Project in central west NSW.

ASM Managing Director, David Woodall said: “This is a significant result given the temperatures required for the production of dysprosium metal. Our team has now successfully produced the key permanent magnet rare earth products (dysprosium, praseodymium and neodymium metals and alloys) which will be supplied from our Dubbo Project.”

“Now that the protocol for the production of dysprosium metal has been completed, our team led by Professor Lee, will focus on the production the ferro-dysprosium alloy, which is key in the production of high-temperature NdFeB magnets. Our focus now is to produce zirconium metal by the end of September, Mr Woodall said.

The ASM metallisation process uses significantly less energy and has less impact on the environment than existing industry-standard metallisation processes. This innovative process has been used to produce metals of the planned products from ASM’s Dubbo Project including zirconium, hafnium, and rare earths for permanent magnet alloys in the laboratory. Titanium and the key rare earth permanent magnet metals neodymium and praseodymium have been produced in the commercial pilot plant with dysprosium and zirconium scheduled for later this month. ASM and Ziron Tech continue to finalise the detailed documentation in relation to the acquisition of Ziron Tech with the transaction expected to be completed by the end of October 2020.

Highlights:

Highlights: