Highlights:

Highlights:

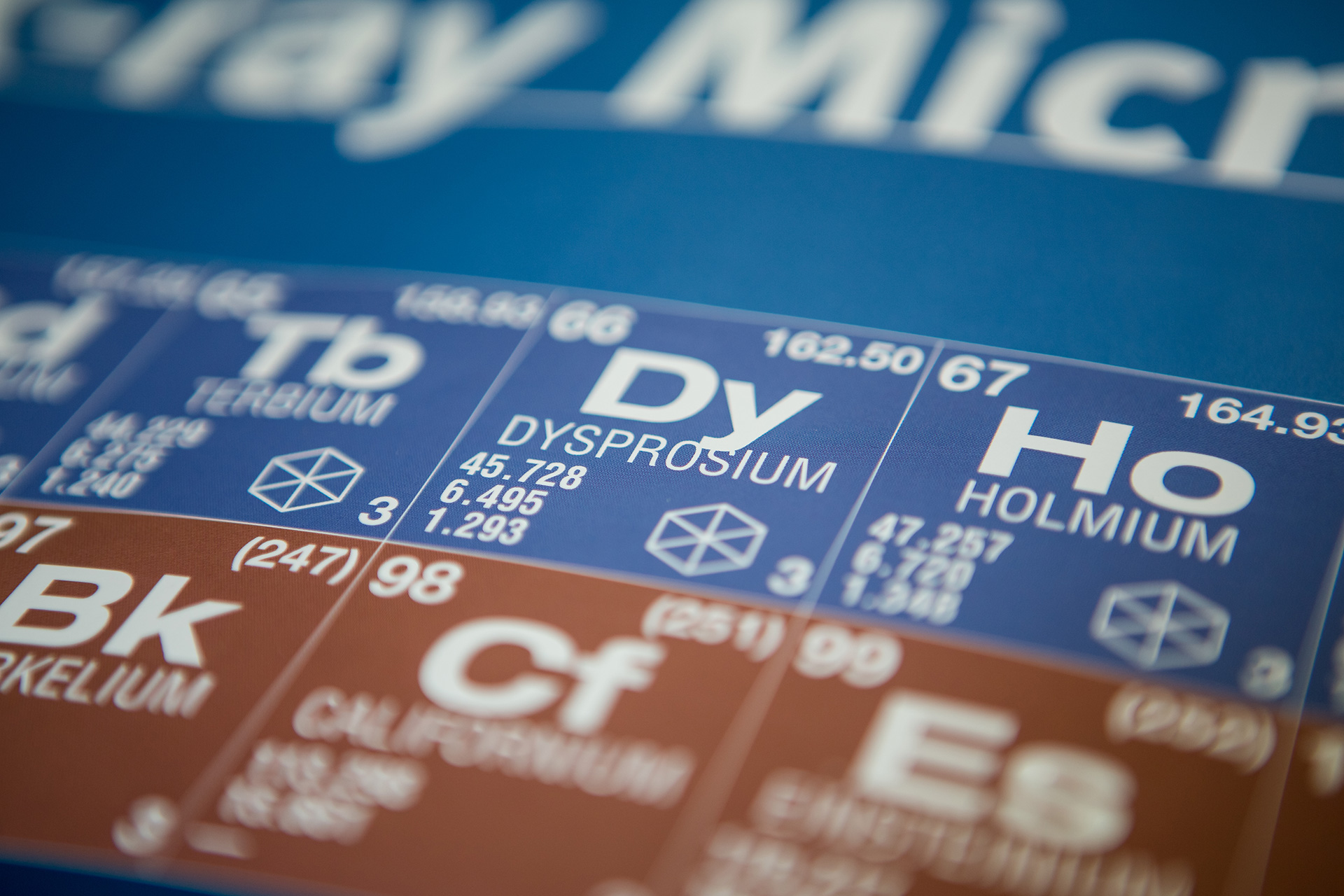

- ASM produces 7.5kg of heavy rare earth dysprosium metal

- Dysprosium metal assay – 99.53%

- Metallisation of ferro-dysprosium and zirconium progressing

ASM, through its partner Ziron Technology Corporation (Ziron Tech), has successfully produced 7.5 kg of a high purity dysprosium metal at its commercial pilot plant in South Korea.

After producing 0.76 kg of the heavy rare earth metal last month, this second run confirms that it can be done at scale, marking the completion of the final key permanent magnet metals to be produced at the Ziron Tech facility. ASM has now produced neodymium, praseodymium, neodymium praseodymium alloy and dysprosium, all key for permanent magnets, through the commercial pilot plant using its innovative metallisation process.

Work has commenced on the production of ferro-dysprosium and zirconium metals. These are anticipated to be the final products metallised from material sourced from the Dubbo Project in central west NSW.

ASM Managing Director, David Woodall said: “ASM is progressing further in its development to become an integrated mine to metal business, with the successful production of the heavy rare earth metal, dysprosium. With the production of these key permanent magnets metals and metal alloys, and the development of zirconium metal production, ASM is one step closer to converting all products from the Dubbo Project into value-adding metals.”

“Our focus is now on commencing the design and construction of a 250 kg per day continuous metal plant in Korea. This is the first phase of our strategy to develop a 3,000-5,000 tonne per year plant designed to meet some of the demand for critical materials in the Korean manufacturing sector. ASM continues to advance discussions for a potential partner in the metal business,” Mr Woodall said.