Highlights

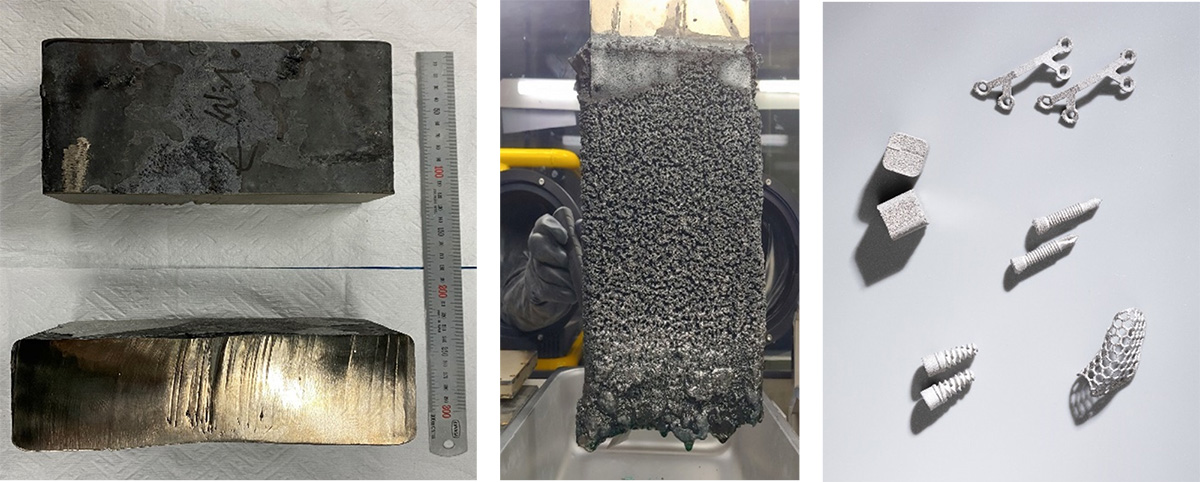

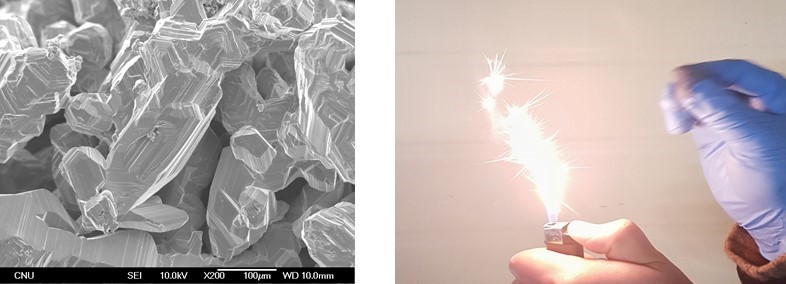

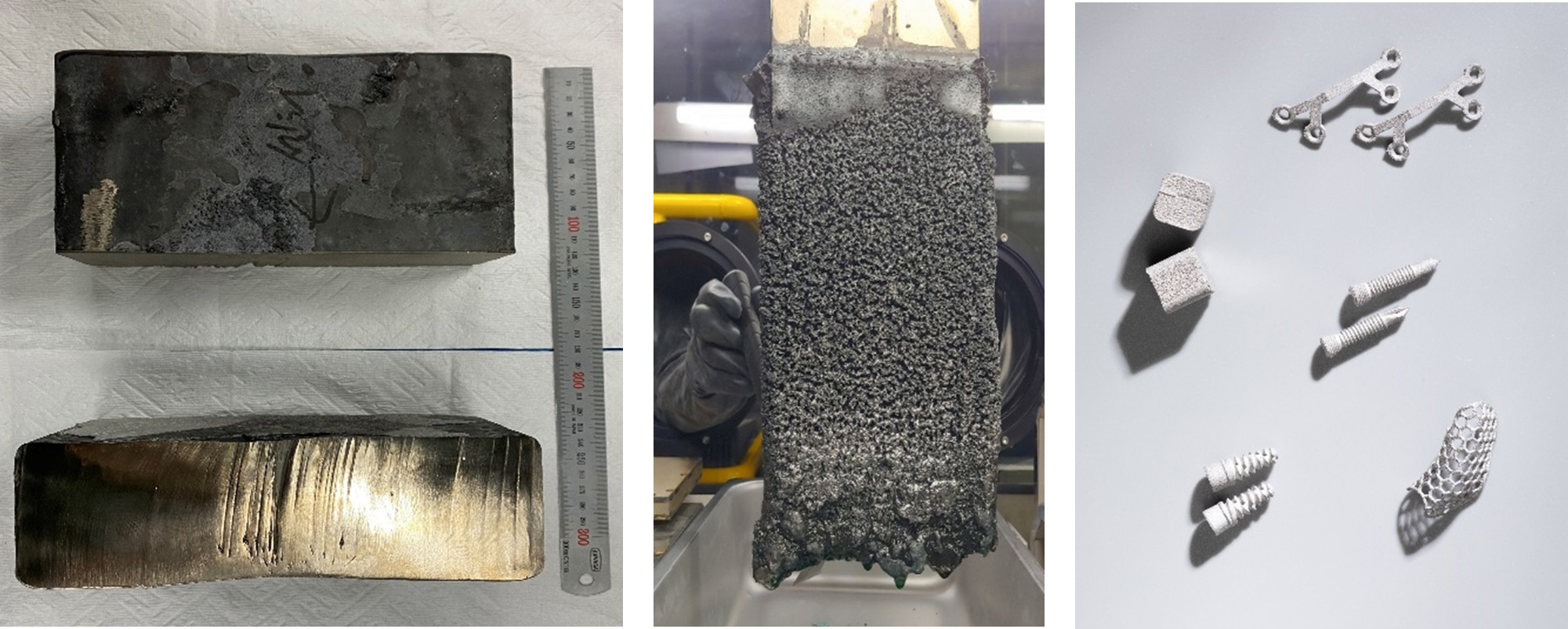

- Independent 3D-printed metal part producer HANA AMT has confirmed the high purity of ASM’s titanium powder

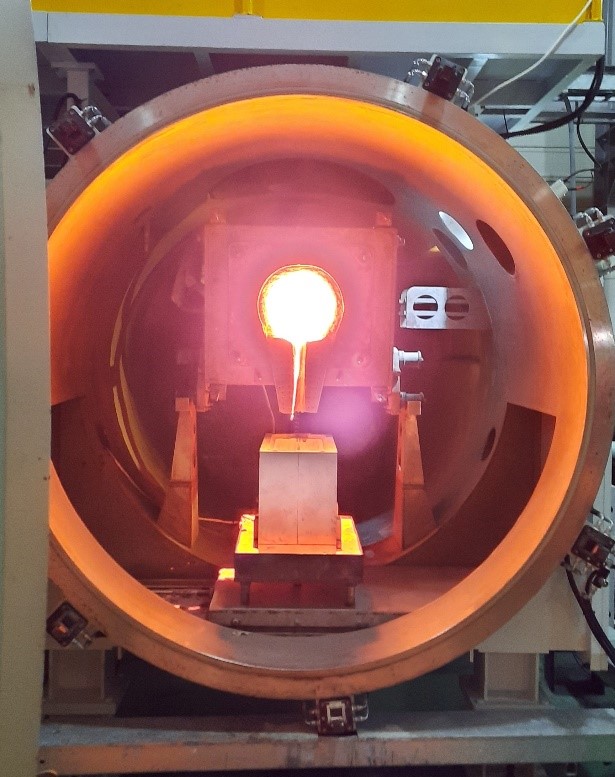

- A 75kg/day run of titanium (Ti) metal powder was successfully produced by Ziron Tech at a pilot scale (metal purity 99.918%)

- Significant environmental benefits of ASM’s novel metal process were confirmed by HANA AMT

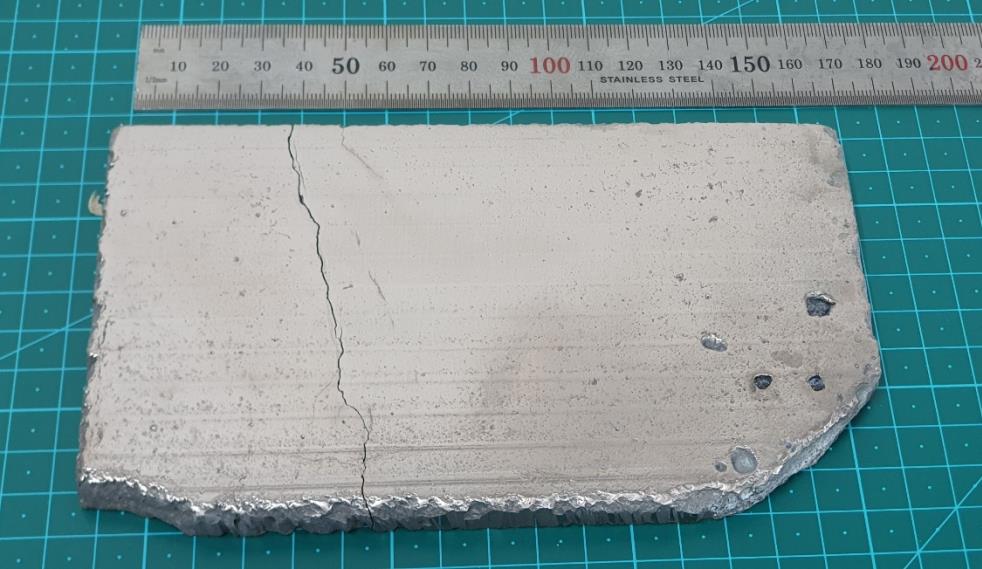

ASM has received confirmation of its high-purity titanium powder from HANA AMT, a Korean 3D printing group. HANA AMT performed a detailed analysis of 20kg of the titanium powder, confirming a purity of 99.918%.

The titanium metal powder assayed came from a run of 75kg produced at ASM’s metallisation pilot plant during January 2021. ASM and HANA AMT have signed a non-disclosure agreement as they progress negotiations towards an initial 1,500 tonne per year offtake agreement for titanium metal powder.

Contributing to the progress of this agreement, the independent assay analysis of ASM’s titanium powders demonstrated the following comparison with industry standards (table 1):

|

Titanium Metal Powder |

||

| Elements | Industry Standard – %* | ASM Ti Powder – % |

| Ti | Balance | 99.918 |

| Fe | < 0.010 | 0.002 |

| Al | < 0.005 | 0.003 |

| Cr | < 0.005 | 0.003 |

| Mo | < 0.005 | 0.001 |

| Mn | < 0.005 | 0.001 |

| Ni | < 0.005 | 0.002 |

| Zr | < 0.005 | 0.001 |

| Cu | < 0.005 | 0.003 |

| Co | < 0.005 | 0.002 |

| B | < 0.005 | 0.001 |

| C | < 0.005 | 0.001 |

| Ni | < 0.010 | 0.009 |

| H | < 0.005 | 0.003 |

| O | < 0.080 | 0.050 |

Table 1 – Assay Comparison completed by HANA AMT

* ASTM B299 – Standard Specification for Titanium

ASM managing director, David Woodall said, “This independent review of ASM’s titanium metal powder is a great validation of our patented metal process, confirming the high purity and the environmental benefits of the metal ASM can produce for the manufacturing sector in Korea. We look forward to progressing negotiations and continuing discussions with other potential offtake and strategic partners during our time in Korea.”

“Our team continues to work closely with the Korean Institute of Rare Metals (KIRAM) to produce sample permanent magnets for the Korean market to review over the coming weeks. This is a promising start of the year, with 2021 a foundation year for ASM, as we progress our vision to become a fully integrated critical metals producer – supplying metals from the mine direct to manufacturers, through the delivery of the Dubbo Project and the establishment of our metals business.”

Highlights

Highlights

Highlights:

Highlights:

Highlights

Highlights